The Power of Centrifugal Screens: Enhancing Efficiency and Quality in Filtration

In various industries, the need for effective separation processes is critical to ensuring product quality and operational efficiency. One technology that has gained significant traction in filtration applications is the centrifugal screen. These innovative devices harness centrifugal force to separate solids from liquids, making them invaluable in sectors such as food processing, pharmaceuticals, and chemical manufacturing. In this article, we’ll explore the fundamentals of centrifugal screens, their applications, and their benefits.

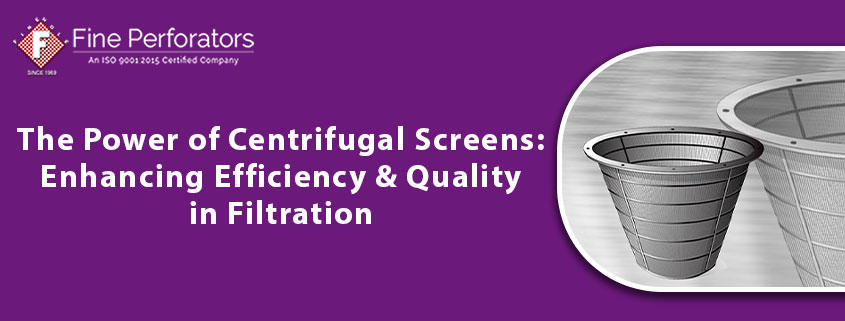

What Are Centrifugal Screens?

Centrifugal screens are filtration devices designed to separate solid particles from liquid streams. They operate on the principle of centrifugal force, which is generated when the screen is spun at high speeds. As the liquid enters the screen, the centrifugal force pushes the solids against the screen’s mesh, allowing the clean liquid to pass through while retaining the larger particles.

Key Components:

- Rotating Drum: The heart of the centrifugal screen, where the separation occurs. The drum spins at high RPMs, generating the necessary centrifugal force.

- Mesh Screen: The filtration medium that retains solids while allowing liquids to flow through. Different mesh sizes can be selected based on the application requirements.

- Inlet and Outlet: These allow for the introduction of the liquid mixture and the collection of the filtered liquid, respectively.

Applications of Centrifugal Screens:

Centrifugal screens are versatile and can be utilized across various industries. Here are some common applications:

- Food Processing

In the food industry, centrifugal screens are used for separating pulp from juices, filtering oils, and clarifying liquids. They ensure that products meet safety and quality standards while optimising yield.

- Pharmaceuticals

In pharmaceutical manufacturing, maintaining purity is paramount. Centrifugal screens help in the filtration of active ingredients and solvents, ensuring that the final products are free from contaminants.

- Chemical Manufacturing

Chemical processes often involve the separation of solids from liquids. Centrifugal screens facilitate this process, improving efficiency and reducing waste.

- Wastewater Treatment

Centrifugal screens play a crucial role in municipal and industrial wastewater treatment by separating solids from effluents, thus helping in compliance with environmental regulations.

Benefits of Using Centrifugal Screens:

- High Efficiency

Centrifugal screens operate at high speeds, allowing for rapid and efficient separation. This leads to increased throughput and reduced processing times compared to traditional filtration methods.

- Customization

These screens can be tailored to fit specific applications, with options for different mesh sizes, materials, and designs. This customization ensures optimal performance based on the unique needs of each process.

- Reduced Maintenance

Centrifugal screens are designed for easy cleaning and maintenance. Their straightforward design allows operators to quickly disassemble and reassemble the equipment, minimizing downtime.

- Improved Product Quality

By effectively removing unwanted solids, centrifugal screens enhance the quality of the final product. This is especially important in industries where purity and safety are critical.

Conclusion

Centrifugal screens represent a powerful solution for solid-liquid separation across multiple industries. Their high efficiency, customization options, and ability to improve product quality make them an essential tool in modern filtration processes. As industries continue to evolve and demand greater efficiency, the role of centrifugal screens will undoubtedly expand, contributing to more streamlined operations and enhanced product integrity.

If you’re considering upgrading your filtration systems, centrifugal screens from Fine Perforators, the premier manufacturers and exporters of Centrifugal screens, might be the key to unlocking new levels of efficiency and quality in your operations.

Leave a Reply

Want to join the discussion?Feel free to contribute!